PRODUCTS

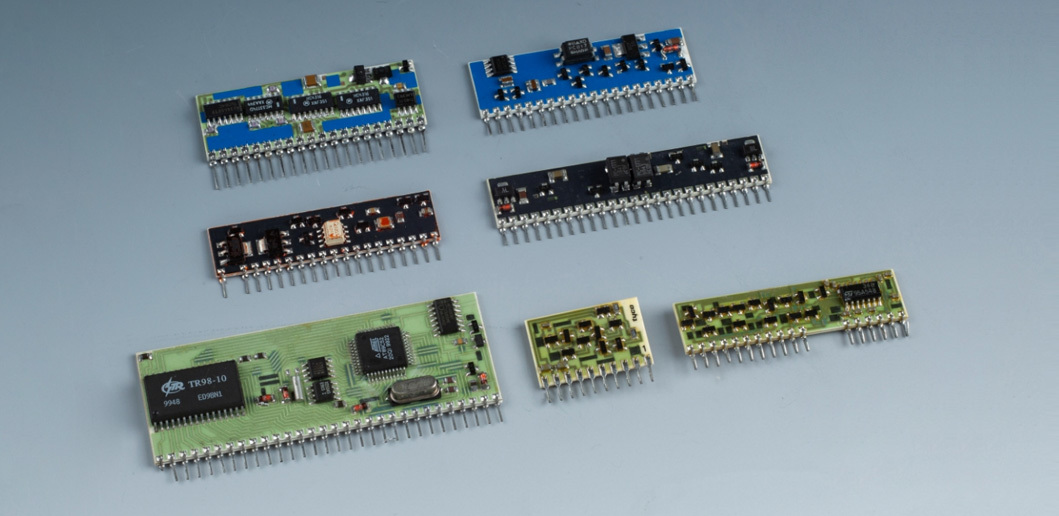

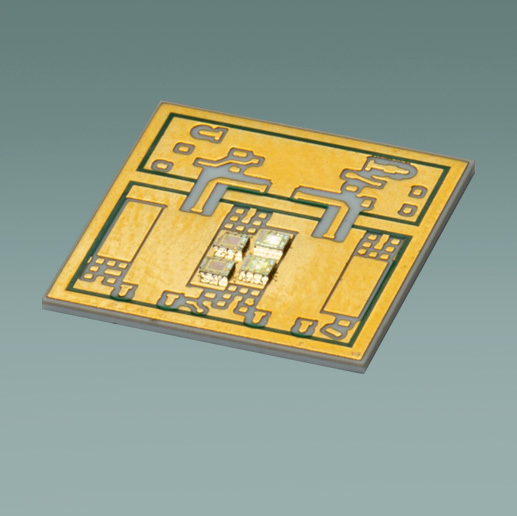

Focus on thick film hybrid integrated circuits and custom services

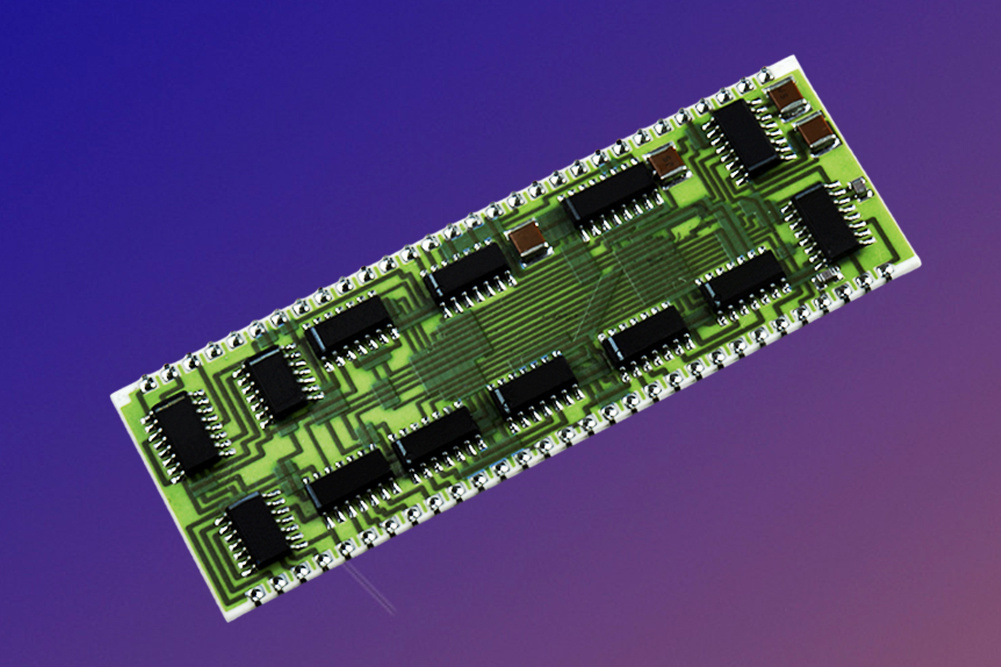

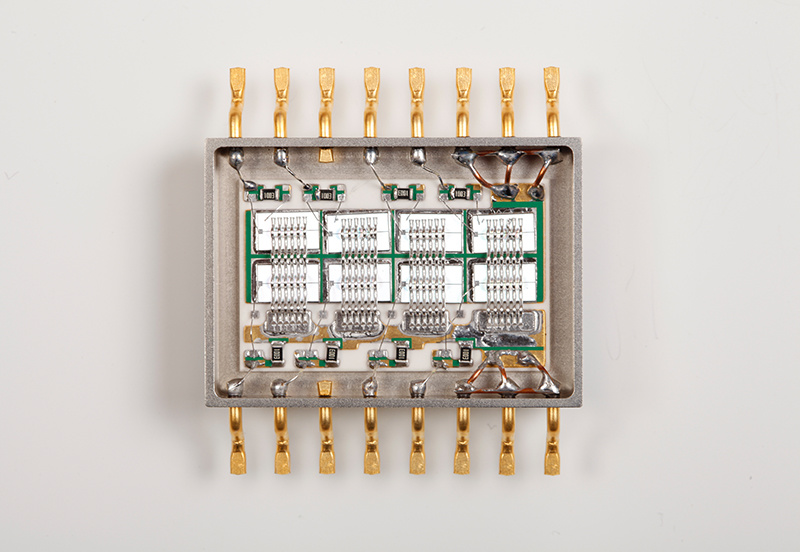

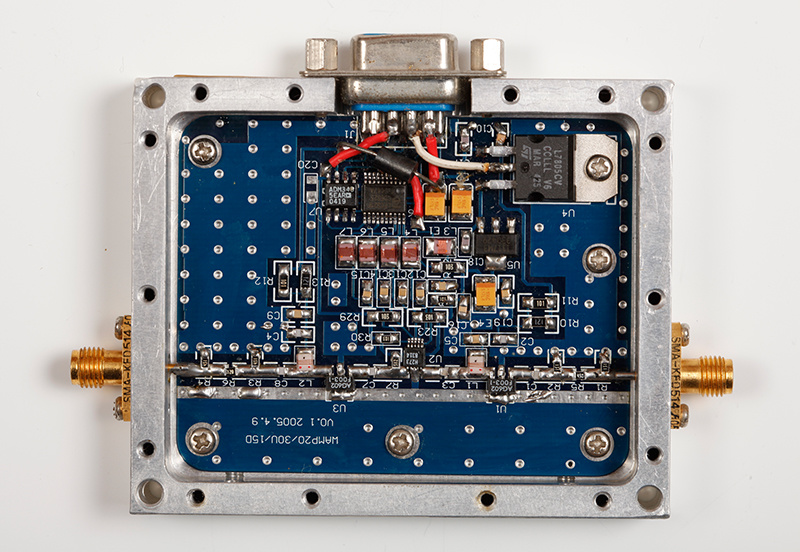

Thick film hybrid integrated circuit is a kind of micro electronic functional components, it is the use of ceramic substrate as the substrate, with all kinds of palladium silver conductor paste, platinum silver conductor paste, gold conductor paste and ruthenium series resistor paste, etc., using screen printing, 850 degree high temperature sintering and laser trimming resistor thick film process on the same substrate to make passive network, and on the assembly of discrete semiconductor device chips, monolithic integrated circuits or microcomponents, and then packaged into a hybrid integrated circuit.

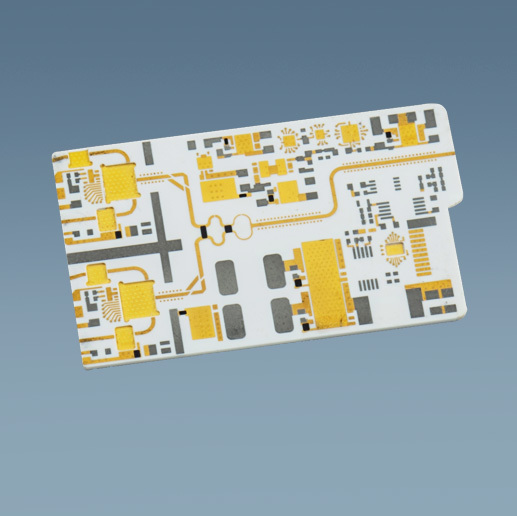

Learn moreLow Temperature Co-fired Ceramics (LTCC)

Focus on thick film hybrid integrated circuits and custom services

Learn moreLocalization board "one-stop" service

Focus on thick film hybrid integrated circuits and custom services

Learn moreFocus on thick film hybrid integrated circuits and custom services

Learn moreFocus on thick film hybrid integrated circuits and custom services

Learn moreApplication Industries and Solutions

Focus on various application fields and provide stable, efficient and reliable customized solutions

News

2024-06-23

Development of High Frequency Switching Power Supply Technology for Communication

The integration and miniaturization of high-frequency switching power supply for communication is the main trend of future development. The power density will be larger and larger, and the requirements for technology will be higher and higher.

2024-06-23

On the approximate definition of ripple in low ripple power supplies

Since the DC stable low ripple power supply is generally formed by the AC power supply through rectification and voltage stabilization, it is inevitable that there are some AC components in the DC stable quantity.

2024-06-23

Application and basic principle of module power supply noise filter

There are all kinds of EMI noise in 220V/50Hz AC power grid or 115V/400Hz AC generator, among which artificial EMI interference source.

About Us

Company establishment

Self-built workshop area

Laboratory Testing Center

Employee

Qualification Certification

Customer Service

Waco Electronic Module (Shenzhen) Co., Ltd.

Waco Electronic Module (Shenzhen) Co., Ltd. was established on March 31, 1987 as a wholly-owned subsidiary of Hangjin Technology Co., Ltd. The company is located in Nanshan Zhiyuan, with a registered capital of 14.5638 million yuan and a total asset value of 0.35 billion yuan. Is a national high-tech enterprise, the main business includes the development, design, production and sales of hybrid integrated circuits (including thick film circuits, LTCC) micro assembly (including thick aluminum wire bonding, gold wire bonding, testing, packaging, etc.), SMT, etc., products related to communications, automotive electronics, medical electronics, industrial control, signal processing, power module, high voltage surge suppression, variable speed motor control and other fields.