Low Temperature Co-fired Ceramics (LTCC)

Products involved in the defense industry, communications, automotive electronics, medical electronics, industrial control, signal processing, power module high-voltage surge suppression, variable speed motor control and other fields.

Classification:

Product Details

LTCC's technology is to make low-temperature sintered ceramic powder into a precise and dense green porcelain tape through grinding and casting, on which the required circuit patterns are made by processes such as machine punching, laser drilling, through-hole filling, precision conductor paste printing, etc., and a plurality of passive components (such as low-capacitance capacitors, resistors, couplers, etc.) are embedded in multi-layer ceramic green porcelain sheets and then laminated together, sintering and cutting at 850 ℃ to make high-density circuits that do not interfere with each other in three-dimensional space, and then mount various packaged ICs, bare chips and various active devices on their surfaces to make passive active integrated functional modules, which can further miniaturize and densify the circuits, and are especially suitable for high-frequency communication components, high-frequency filters and microwave antennas.

Product features:

Higher integration, excellent high-frequency characteristics, thermal stability, high reliability, and built-in passive devices.

Technical process:

|

Substrate material |

Ferro A6M raw porcelain tape |

|

conductor paste |

Ferro all-gold series, all-silver mixed series |

|

resistance paste |

Ferro FX87-Series |

The main performance table of raw porcelain belt material:

|

LTCC Type |

layer sintering thickness (mm) |

Shrinkage X- Y,% |

Shrinkage (Z,%) |

Dielectric constant |

Insulation resistance (Q) |

breakdown voltage (V/layer) |

sintered density (g/m3) |

Coefficient of thermal expansion (ppm/°C |

tangent loss |

Bending strength ( Pa) |

coefficient of thermal conductivity (W/m.k) |

warping degree |

|

FerroA6M |

0.095 |

15.2 |

24 |

5.9 |

>1012 |

5000 |

2.45 |

7 |

0.20% |

170MPa |

2 |

0.30% |

Design Specification

|

co-fired material |

All gold system |

|

|||

|

hybrid system |

Outer layer: Pd/Ag or gold conductor, inner layer: Ag conductor |

||||

|

Post-firing material |

Printed on the sintered TCC substrate, generally (Pd/Ag) |

||||

|

LTCC Thickness |

Minimum: 0.5mm(5 layers), maximum: 3mm(30 layers) |

||||

|

LTCC raw tile size |

The general maximum size is 203.20X203.20X0.127mm, can be cut |

||||

|

Dimensional error |

The error after cutting is generally/-0.10mm |

||||

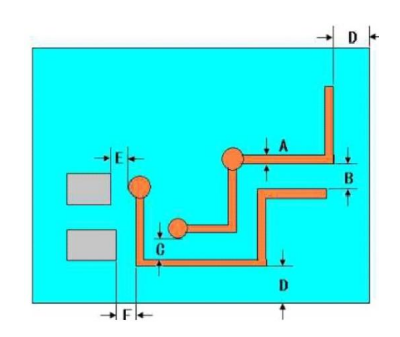

Wiring Design Criteria

|

Features |

|

Standard |

Minimum |

|

A |

Line width |

0.2 |

0.1 |

|

B |

Line spacing |

0.2 |

0.1 |

|

C |

Line Hole Distance |

0.2 |

0.1 |

|

D |

Distance from line to substrate edge |

0.3 |

0.2 |

|

E |

Distance from pad to via footprint |

0.2 |

0.1 |

|

F |

Distance from weld zone to conductor strip |

0.2 |

0.1 |

|

|

Through hole size |

Generally 0.15,0.20,0.30 |

|

|

|

Minimum through hole spacing in the same layer |

2.5 x0, or 0.5 |

|

|

|

Minimum via spacing between adjacent layers |

2.0x0 |

|

|

|

Hole-to-edge distance |

3x 0 minimum, or hole margin edge 0.38 |

|

Unit: mm

Key Words: Hybrid integrated circuit

Previous:

Related Products

Low Temperature Co-fired Ceramics (LTCC)

Localization board "one-stop" service

Message

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.